TLDR; make your plated thru-holes 0.8mm diameter for these components.

Long Version:

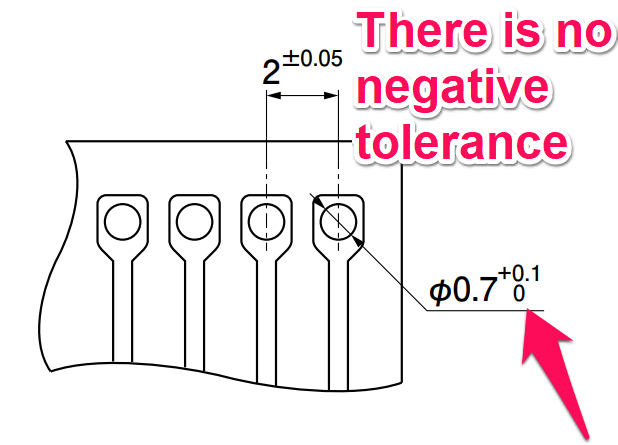

Many of our customers like using your PH series connectors on their circuit boards. According to page 1 of JST’s datasheet, these holes are recommended to be 0.7mm diameter plated-thru-holes.

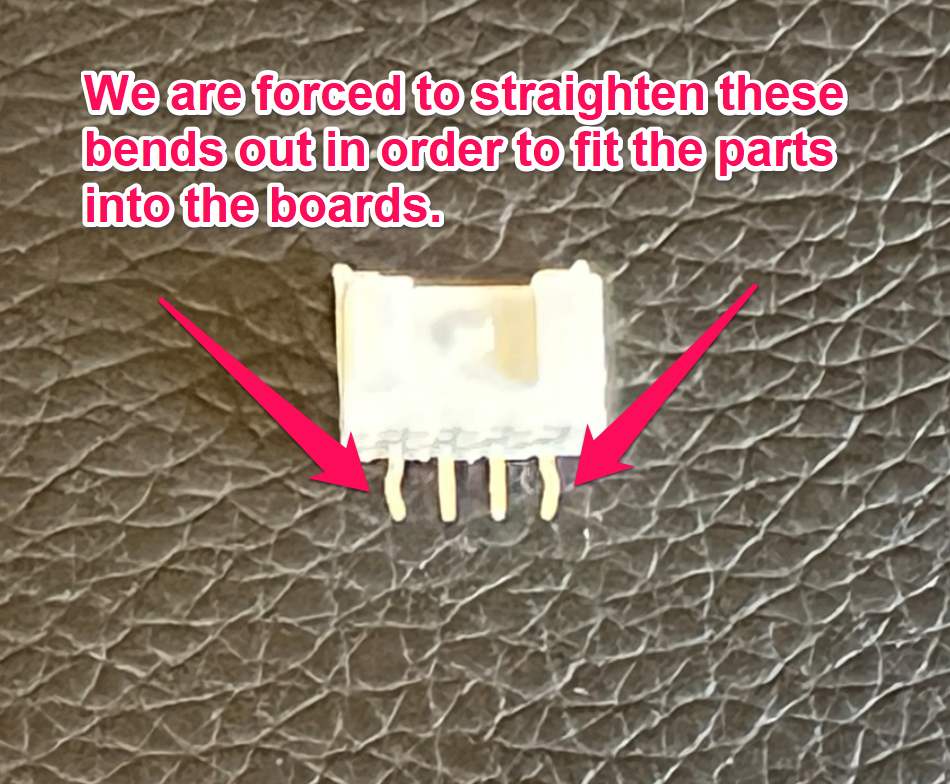

The trouble is, this hole is too small for the bent outside pins of these connectors. When they get bent, they do not fit into the hole and we find ourselves having to use pliers to squeeze this bend away and make it straight in order to get it into the hole. If we don’t, we end up with either very sore thumbs or damaged components, and oftentimes both.

If you look closely, you will notice that JST has provided a positive tolerance of 0.1mm but no negative tolerance. Pretty much every PCB fabricator we have ever worked with has told us that they have a +/- tolerance of 0.1mm for plated-thru-holes. Meaning boards designed with a 0.7mm diameter hole will end up with holes as small as 0.6mm and as large as 0.8mm and still be within their manufacturing tolerance.

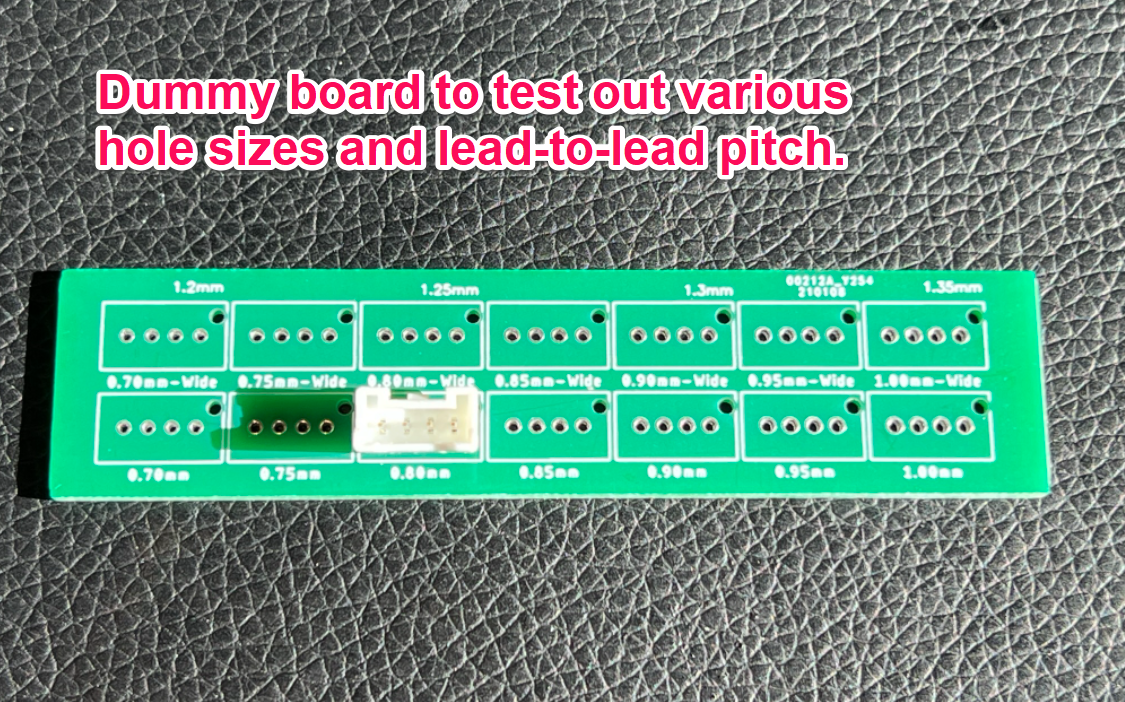

We went so far as to create a dummy board to evaluate the best size to make these holes for repeatable results. We've found that making these holes 0.8mm means that we can properly assemble boards without removing the bend on the outside leads of the component.

So for the sake of all of our sore thumbs, please adjust your footprint libraries to make these 0.8mm plated thru-holes :)