SMT

Worthington Assembly has a world class SMT process. Even though we are small we are prepared for anything; Double-sided, flipchip, PoP, 0.3mm fine pitch IC's, BGA's, you name it, we've seen it and we can handle it.

Our equipment is accurate down to 25 microns at 3 sigma (that's technical jargon for really accurate) and we have the capacity to crank through 17,500 components per hour.

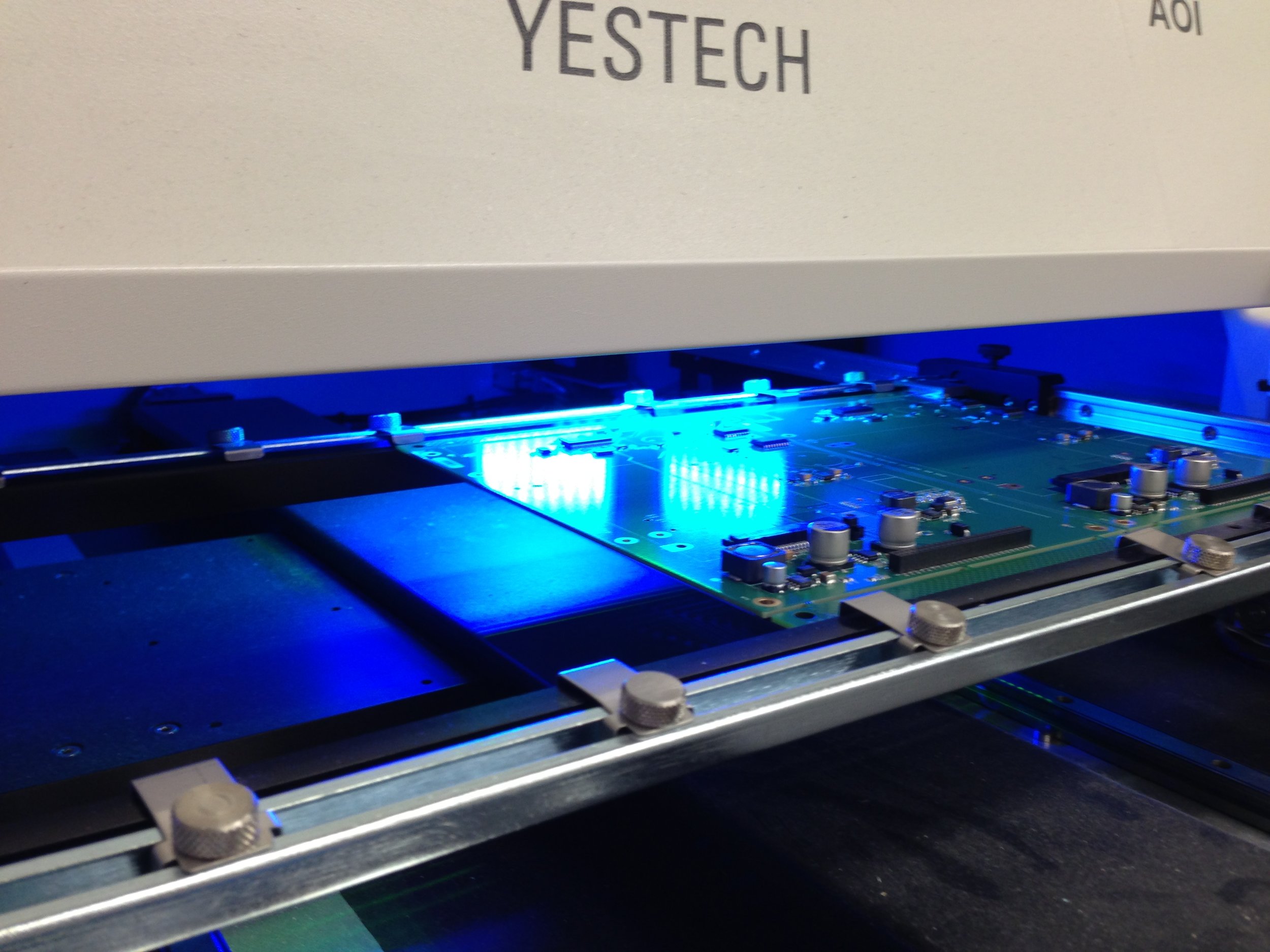

We test each resistor and capacitor before it is placed. This means that even though we sometimes cannot read any markings on these components, we can still verify that the correct value was placed where it should be. Then, each and every circuit board gets an Automated Optical Inspection (AOI). This means we read the markings of every single component placed on the board and verify that it's the correct part and it's in the correct orientation.

You will get a 100% correctly assembled circuit boards or we will repair any issues found. Shoot us an email at info@worthingtonassembly.com or give us a call at (413) 397-8260. Or better yet, visit our Request A Quote page.