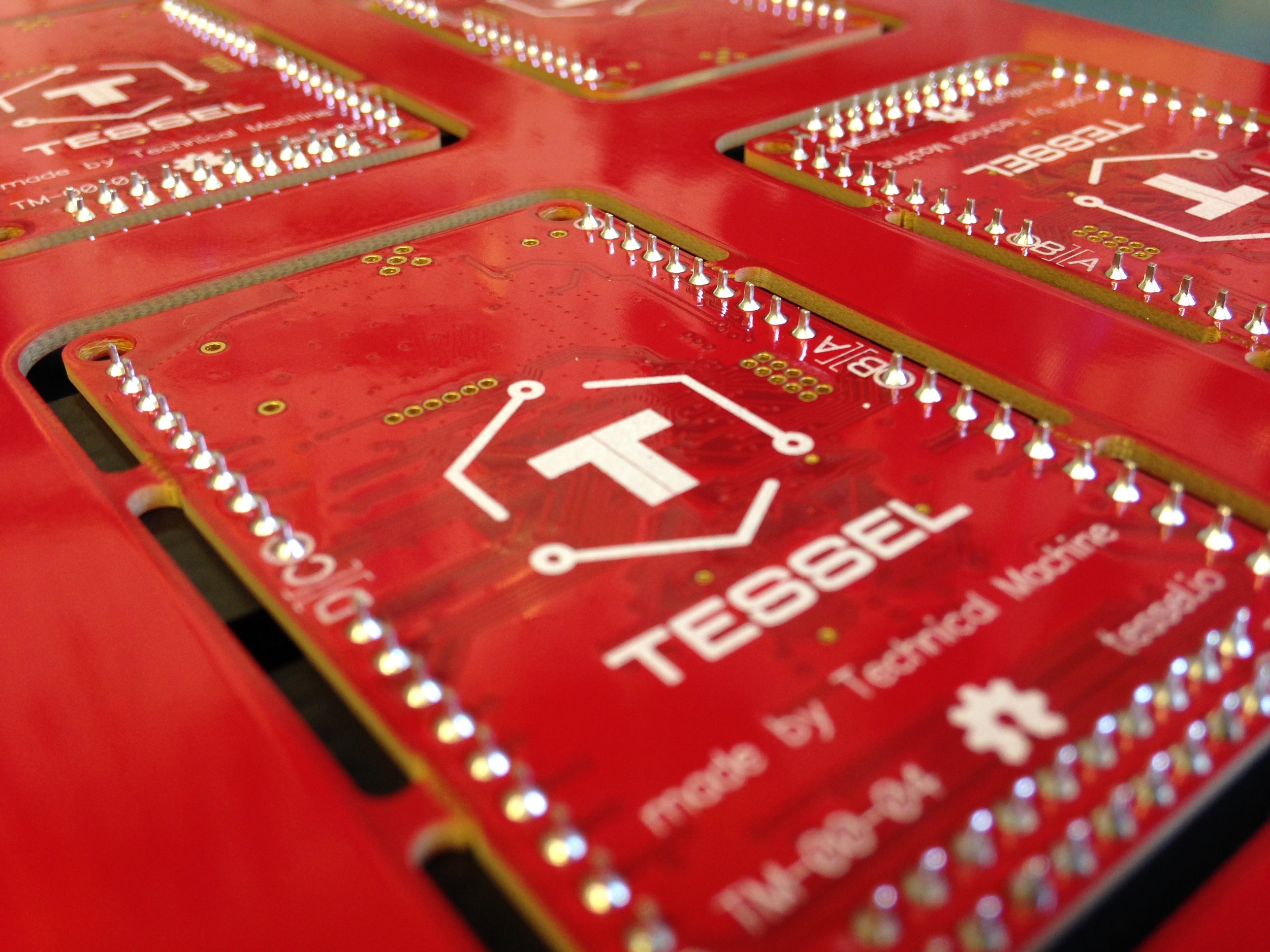

Thru-Hole

Nearly every single circuit board we assemble has thru-hole components in addition to surface mount components. Some things still require an old school thru-hole component.

Once a board has been populated it gets put onto our selective soldering machine. This machine is so cool. If you're ever in New England, please come visit us to see this in person. It's a tiny solder fountain attached to a big robot. The robot moves the fountain in place and the fountain solders the thru-hole components to the circuit board. So the resulting solder joint is reliable and repeatable.

We've outfitted our factory to handle these components. All thru-hole components are inserted by hand. There still aren't fancy enough robots to do it for us. So in order to prevent messing this up we use a dedicated slide line with a verified setup to ensure that the correct part numbers are going to be put into the circuit board in the correct locations.

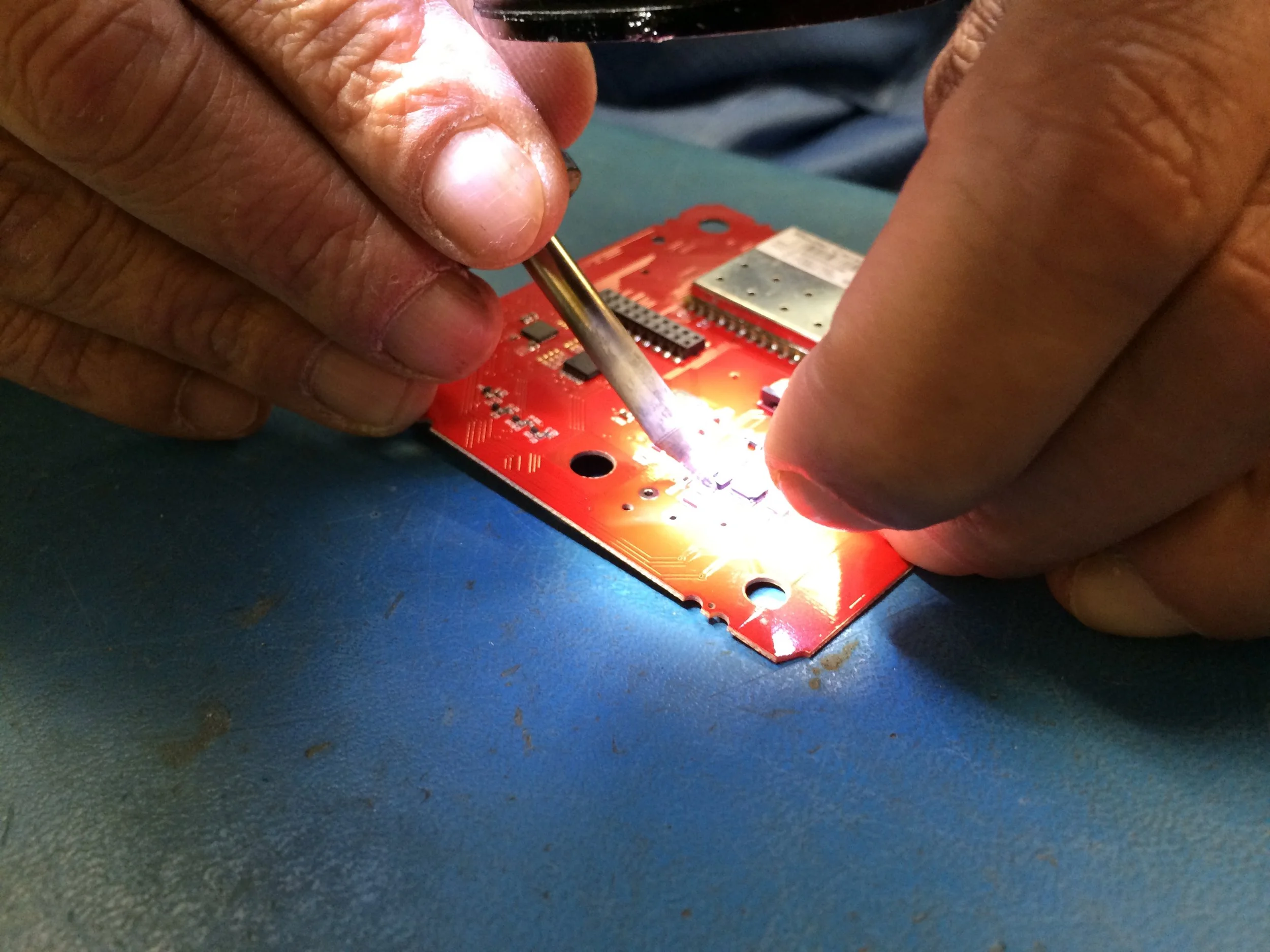

All of our thru-hole boards get visually inspected for any defects. If anything is found that needs more attention, it will be repaired and reinspected. Our policy is "Make it look like jewelry", so you can expect a beautifully soldered circuit board.

Feel free to shoot us an email at info@worthingotnassembly.com or give us a call at (413) 397-8260. Or better yet, visit our Request A Quote page.